Product Description

Very High Bonding Double Sided Tape

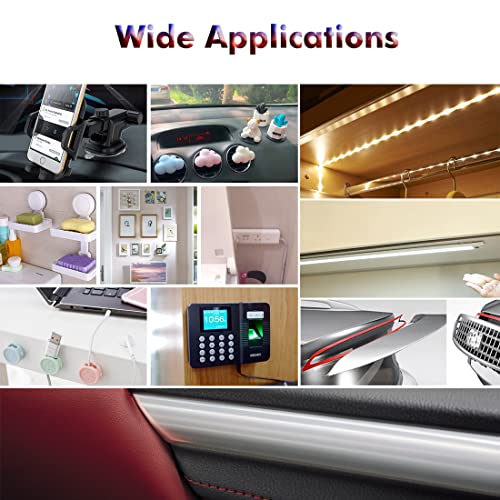

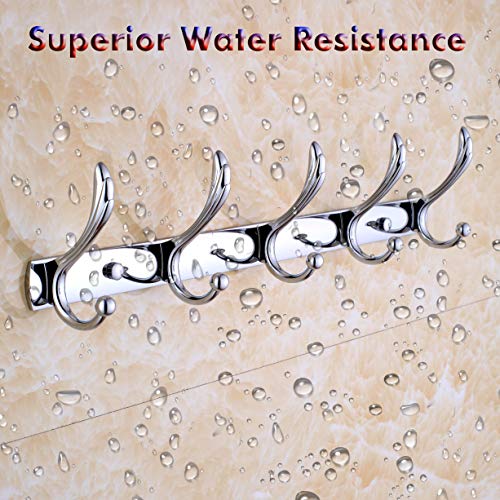

Industrial Grade 2 Sided Mounting Tape – Widely Used:

Very high bonding tape works extremely well on smooth surfaces and widely used for LED strip lights, trims, car registration plates, name plates, address plaques, signs, emblem, car holders, mosquito/bug screen, metal mailbox, mirrors, hangers, tooth brush holder, photo frames, power strip and other automotive home office decorations.

This double sided mounting tape is an industrial grade Acrylic foam tape, more stable and better initial adhesion which is good for permanent and reliable installation indoor, particularly in exterior applications where extreme weather, moisture and adhesive is needed. The longer applied the stronger it will hold.

Super sticky strength that can withstand moderate to heavy mounting with peel adhesion up to 20lb/in and tensile strength up to 90 lb/square inch as tested on stainless steel. Holding weight is based on objects with a maximum depth of 0.75”.

The PE film liner might be difficult to peel if you do not have nail; you can Use a knife to cut out the backing film a little bit or Pinch and stretch a corner of the adhesive until the backing liner lifts from the tape for easier liner removal.

WARM THE ADHESIVE SIDE UP IN COLD WEATHER BY HAIR DRYER FOR BETTER INITIAL BONDING.

Industrial, Home, Car and Office Applications:

Simple Steps for Application:

1. Clean the surface as per application guidelines and keep it dry.

2. Pinch and stretch a corner of the adhesive until the backing liner lifts from the tape for easier liner removal or use sharp tool to cut an open on the film backing liner.

3. Cut the right size you want and stick it on the surface of object, if you are going to mount over size and heavy object, let the tape cure for at least 12 hours to create a secure bonding first and then stick to the wall.

4. Give a HARD PRESS if you are sure about the position to objects and wall.

5. For some surface if the tape does not work, spray Adhesion Promoter first then stick the tape.

NOTE: Never use this tape on any type of PAINTED DRYWALL which might cause damage to the paint.

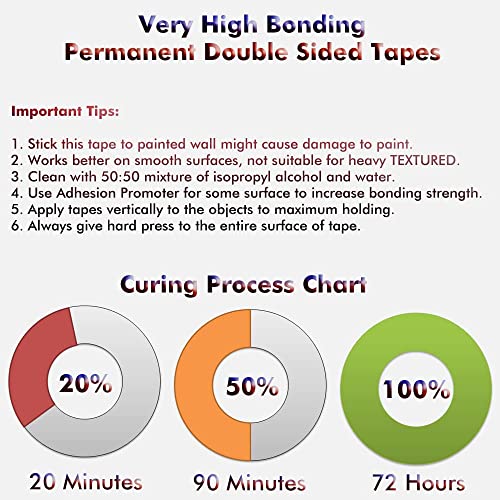

Acrylic Tape – Curing Process for Adhesion Percentage:

The surfaces should be thoroughly cleaned with a 50:50 mixture of isopropyl alcohol and water. Accomplished when temperature is between 70° and 100°F (21°-38°C) and the bond is allowed to dwell 72 hours. Initial tape application to surfaces at temperatures below 50°F (10°C) is not recommended.

What should I pay attention to make my application work? 1. Make sure the applicaton temperature is around between 70° and 100°F. 2. Press the tape against the object and wall as hard as you can. 3. Use a plastic roller to clean the air between object and adhesive. 4. For some surface if the tape does not work, spray Adhesion Promoter first then stick the tape. 5. Permanent double sided mounting tape, not suitable for temporary use. 6. Never use this tape on any type of painted wall or it will damage your painting.

Specification of Size:

1. Model Number: Comparable with 5925 and 5952.

2. Roll Width: 1/2 Inch, 1.0 inch and 2 Inches.

3. Color: Red film backing.

4. Wrap packed.

What steps should I follow while applying?

1. Clean the surface as per application guidelines and keep it dry.

2. Cut the desired and stick it on the surface of object if you are going to mount over size and heavy object for at least 12 hours to create a secure bonding first and then stick to the wall.

3. Give a hard press if you are sure about the position.

Temperature Resistance

Short Term: (minutes, hours) 300°F (149°C)

Long Term: (days, weeks) 250°F (121°C)

Easily handling the heat in car at sumer season, working under direct sun and performing the same bonding strength under high watts LED strip lights.

Waterproof and Moistureproof

Excellent water and moisture resistance once the curing process is done, which taken 24 hours. BUT DO NOT stick the tape onto any wet and oil surfaces for initial application, these environmental conditions affect the bonding strength or even weaken the performance; always CLEAN & DRY surfaces first.

Heavy Duty Bonding Strength

Peel Adhesion: 20 lb./in. width (350 N/100 mm) based on stainless steel

Normal Tensile: 90 lb./in.2 (620 kPa) based on aluminum T-block.

Dynamic Shear: 90 lb./in.2 (620 kPa) based on stainless steel.

Product Dimensions : 5.71 x 5.71 x 0.51 inches; 1.41 ounces

Item model number : 5952

Date First Available : May 21, 2020

Manufacturer : 3 M Deutschland

ASIN : B085Y8BDTC

PRODUCT FEATURES: LLPT very high bonding tape (1.2mm/0.047″ thick) is double coated pressure sensitive adhesive tapes for bonding a wide variety of substrates including lower surface energy materials and smooth surfaces, such power coated paints, glass, marble, plastic, tile, wood and lamination; but not good to heavy textured surfaces and painted walls (taken off paints while removal). Excellent temperature resistance, water moisture resistance, permanent bonding strength.

APPLICATIONS: Super sticky strength can withstand moderate to heavy mounting with peel adhesion up to 20lb/in and tensile strength up to 90 lb/square inch as tested on stainless steel; is safe for smooth surfaces and widely used for LED strip lights, trims, car registration plates, name plates, address plaques, signs, emblem, car holders, mosquito/bug screen, metal mailbox, mirrors, hangers, tooth brush holder, photo frames, power strip and other automotive home office decorations.

PRETREATMENT GUIDELINES: For maximum bond strength, the surfaces should be thoroughly cleaned with a 50:50 mixture of isopropyl alcohol and water. Ideal tape application is accomplished when temperature is between 70° and 100°F (21° and 38°C) and the bond is allowed to dwell 72 hours. Initial tape application to surfaces at temperatures below 50°F (10°C) is not recommended.

INSTALLATION: Clean and dry surface first, wipe with ADHESION PROMOTER (ASIN: B098747W2K) if some surface does not work well, apply the tape to objects (warm up the adhesive if weather is too cold) and let it cure for 12 hours then stick to the walls with pressure, “X” shape needed at center for big objects. The longer time applied the stronger the tape will be molding into surfaces of objects.

HOW TO REMOVE: Remove the tape with adhesive remover, spray the adhesive remover around the bonding surface, scrap the tape and residue with plastic scrapper for a neat removal.

Reviews

There are no reviews yet.